Mesh selection and why it matters!

Why is mesh selection so important?

Many printers only give consideration to the mesh count, and ignore the other crucial components of mesh selection. Screen printers who utilize static screens are not given the option from their screen supplier to select the best mesh count, thread diameter, % of open area, or theoretical ink deposit for their particular application. Often this data is not available or is missing for the average printer who buys static (non retensionable) screens from a supplier. This compromises the quality of the print, and ultimately lowers the resale value of your product. We utilize retensionable Newman roller frames, and a selection of static frames that we stretch in house in order to control all of the screen variables. We evaluate all of the characteristics of the mesh before its ever stretched to make a screen. By controlling these variables, we provide a better print, and ultimately greater value for our customers.

The Nitty Gritty

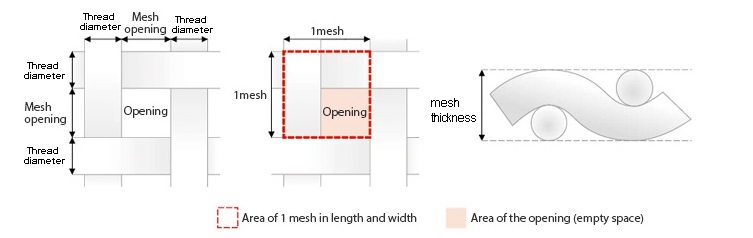

When considering mesh selection for underbase screens, many printers only give consideration to the mesh count. The mesh count, represents the number of threads over one square inch. A 110 mesh screen will have 110 threads in a 1″ space. A 305 mesh screen will have 305 threads over a 1″ space. The more threads per inch, the higher the mesh count and the more detail you can achieve with that given screen. The trade off with increasing detail is opacity, since there are more threads per inch, there is a smaller open area for ink to pass through. This results in a print with higher detail, but less opacity or “brightness”.

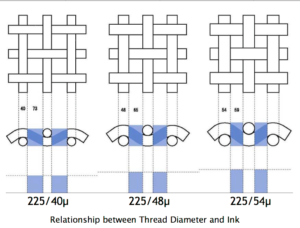

This brings us to the often overlooked component to mesh selection. Thread diameter. It is a misnomer to only represent mesh count. Thread diameter is equally, if not more important. A 110 mesh screen is not just a 110. It is a 110/80 or a 110/71. A 305 is not just a 305, it is a 305/40 or a 305/34. The second number, represents the thread diameter in microns.

A 110/80 mesh screen contains 110 threads per inch, has a thread diameter of 80 microns and a 41% open area.

A 150/48 mesh has 150 threads per inch, a thread diameter of 48 microns and a incredible open area of 51%!

In addition to the mesh count and thread diameter, the open area of screen mesh is also a critical factor when determining ink deposit. A mesh with the proper open area %, should be used for the art that is being printed!

Practical Application:

The thinner the thread, the easier it is to clear the ink from the mesh. When it is easier to clear the ink from the mesh, we can print using high speed and low pressure. When you can print a opaque plastisol ink with low pressure and still get great ink clearance, that is a beautiful thing. The ink provides better opacity as it sits on top of the garment (as intended) rather than being smashed in. Since less ink is needed to do its job, you get a high opacity print with less of a hand, resulting in a better all around print. Plastisol ink should sit on top of the garment, not be smashed into it with

great force. The thicker the thread, the more force is required, either in screen tension or squeegee pressure. Thinner threads also help when printing waterbased or discharge ink. WB and discharge ink need good penetration into the fibers of the shirt to encapsulate the entire fiber and achieve good results. Thin thread mesh, with its high open area % provides much better penetration of the fibers than a standard T (thick thread) mesh.

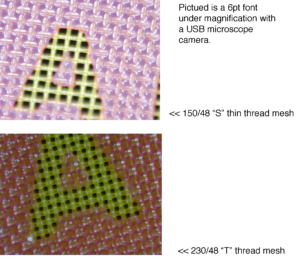

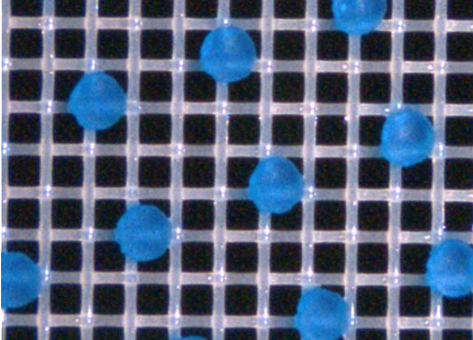

While both a 150/48 and a 230/48 mesh screen can handle the detail of this 6pt font, the best option is to utilize a thin thread mesh to achieve better ink clearance, and higher opacity.

So what are the trade offs? This is the real world therefore trade offs are to be expected. Many shops who use thin thread mesh don’t stick with it. Why? Well, to begin with thin thread mesh is more difficult to source, and it is more expensive than standard mesh. In addition, thin thread mesh is inherently weaker and more susceptible to mishandling. We use special handling techniques and use special tools for ink removal and reclaim to avoid damaging the sensitive mesh. If proper techniques and reclaiming procedures are used, thin thread mesh has great longevity. Often the production manager of a shop will try thin thread mesh, while neglecting to train employees on proper handling. After 5-6 expensive screens are popped in one day they switch back to their “better” mesh. But is is better to have a sub par base screen that results in lower quality? I think not! It is not only beneficial for simple spot color images, but it’s almost imperative if you want to achieve high end prints on the more demanding fabrics that we see in the market today.

After consideration and testing of various mesh counts, thread diameters, and tension levels, we determined to only use thin thread “S-Mesh” at moderate tension (22-27N) for our base plates. We have done extensive testing and have found that thin thread mesh, in particular 135/48, 150/48, and 225/40 provide us with the best base screens. Our 135/40 screens can hold 6% dots at 50 LPI! That is a physical impossibility on a 110/80. And the 135S has a 55% open area, compared to a 110/80 that has a 45% open area. Normally, I like to use higher line screens for halftones, this can easily be achieved on a 150/48 or 225/40 screen. We hold 8% dots at 60LPI on a 150/48 screen. To better hold tonal ranges for high LPI sim process jobs, 225/40 or even 350/30 screens are employed with incredible results. The value of being able to get an opaque white, while at the same time holding high LPI halftones cannot be overstated.

A good understanding of screen mesh can go a long way. Not only for the printer, but also the designer and purchaser of printed apparel. Understanding the print variables in advance of artwork design will better equip you to make choices that provide you with the best product possible. With thin thread mesh, we can do more with less. Often the need for a highlight white or print / flash / print methodology can be eliminated so long as tight control of variables such as screen tension and EOM, (stencil thickness) are tightly maintained. If you want to know more about better designing your art to take advantage of thin thread technology, drop me a line and I’m more than happy to help!

Waterbased Inks Explored

Waterbased inks use water as the main solvent, and may also contain co-solvents and binders which can be petroleum based. The main purpose of these solvents are to carry the pigment, and control the cure rate of the ink film on the garment. Waterbased inks are used primarily on light colors, while discharge or HSA (high solids acrylic) inks are used for darks. Discharge inks are waterbased inks which contain a ZFS activator (zinc formaldehyde sulfate) of a certain percentage. This activator discharges the dye from cotton fibers, the pigment in the ink then replaces that dye with the pigment. The binder acts to bind the pigment into the garment.

Very bright and opaque colors can be achieved with waterbased and discharge inks, this in conjunction with the limited “hand” or feel of the print, makes this ink system very popular for garments that are sold in a retail setting. With discharge systems, Pantone color matching is often problematic and inconsistent. Due to the different dyes used by garment manufacturers, it is very difficult to match pantone colors to a high degree of accuracy, not all garments discharge the same. In addition, there can be variation between lots of shirts even when using the same style from the same manufacturer at a later date. Redyed shirts from manufacturers are not uncommon, and contribute to this issue greatly. This can make it difficult to run a reprint of the same art with exact color accuracy.

Certain garment colors and brands do not discharge well, and since discharge activator only works on cotton fibers, 50/50 blends and triblends do not discharge nearly as well as 100% cotton garments. With that being said, some very interesting effects can be made when you use a discharge ink on a blended shirt. With any ink system, testing is key to achieve the desired results. If you are wanting to use discharge ink on garment colors such as blue, purple green, or any blended garment, you should anticipate a bit more time for testing.

The ink components are often lower in price when compared to plastisol ink, however the cost per print is often more, due to the testing, additional time required for mixing, and extra documentation for each ink blend. In addition, hardeners are needed to strengthen the stencil on the screen, as the inks are very hard on emulsion. Since waterbased inks use water as a solvent, they also have the ability to dry in the screen. Some printers will use lower mesh count screens for this reason, the end result is detail limitation. This is a poor trade off, since the proper use of retarding additives and thin thread mesh, high LPI halftones can be easily achieved. But only when good materials, techniques, and planning are employed.

Often it is advantageous to utilize multiple ink systems and use discharge ink in conjunction with plastisol. Printing a discharge underbase, with plastisol top colors can give you a very thin ink deposit, with a soft hand and great detail. This combination technique works especially well with process and simulated process printing on soft rungspun garments.

Every piece of artwork is unique, and requires a high level of skill to get the best result. There are advantages and disadvantages of every ink system. The more you know about each system and the substrate it is being printed on, the better you can plan your artwork and garment selection to achieve the results that you want.

Recent Comments